ÇINAR RUGS

Çınar Rugs was founded in 1935 in Kayseri by Hayrullah Çınar. The Çınars are members of the Ekincioğlu Family whose ancestors can be traced back to the Seljuks. A love of carpet handcraft has been passed from father to son and now Çınar Rug is operated by the Çınar Brothers; Hasan and Mehmet.

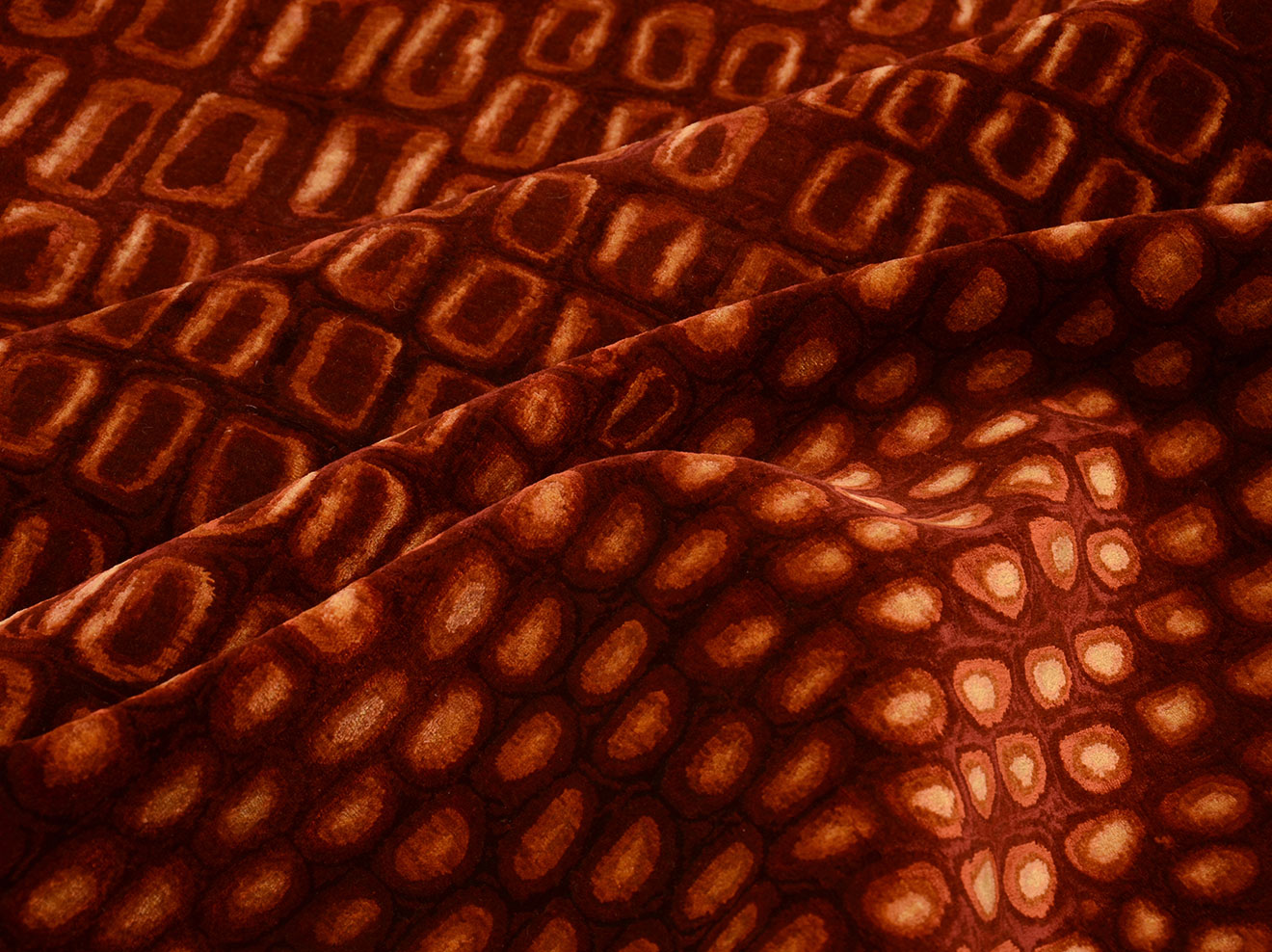

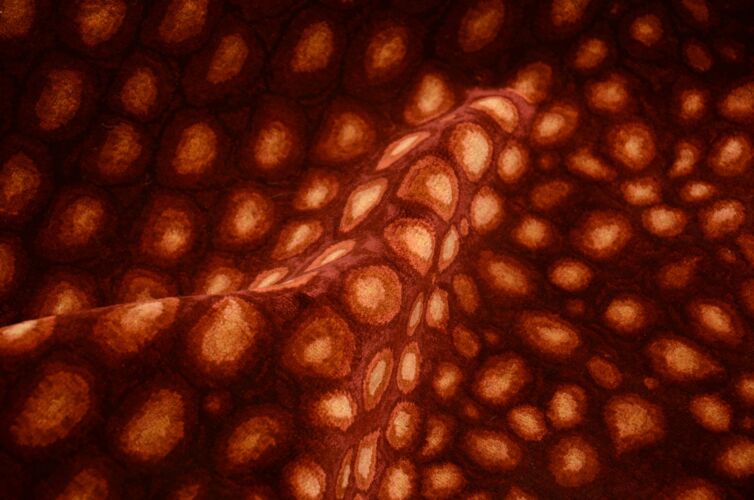

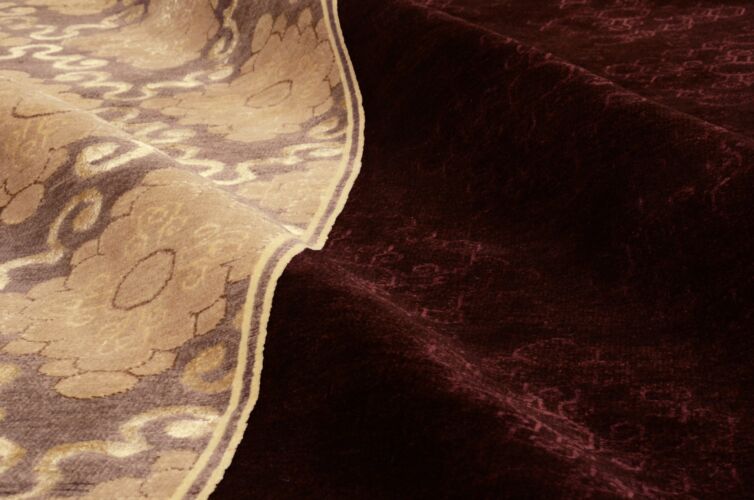

The company’s trademark handwoven wool and silk kilim and carpets have made it one of the leading names in the Turkish carpet sector. Since its founding day, Çınar Rugs has never compromised on its belief in quality. For Çınar Rugs, quality is a way of life and every carpet woven by its skilled artists reflects the highest of standards.

By combining quality and art; Çınar Rugs strives to preserve cultural heritage, moral values, history and Turkish traditions for the coming generations. However, it also hopes to take the Turkish carpet culture to new horizons. Çınar Rug’s exceptional handmade silk and wool carpets have allowed it to surpass its rivals. It is a popular and sought-after brand in Turkey as well as all around the world. In fact, Çınar Rug exports ninety-percent of its products.

Çınar Rug has become a huge enterprise; occupying 14.000 m’ of integrated facilities. Within 150 workshops all around Turkey; 5.000 talented weavers are taking part for the production. The Çınar brothers are behind this success. They have devoted themselves fully to their company and with their past and future projects, they honor the fine traditions of the carpet making business. Creative and meticulous employees, as well as high quality materials, play a significant role in the respected position of Çınar Rug today.

Çınar won “Consumers’ Choice Award”, being the most important award of the contest, with its carpet rich in green shades, named “Sevgi Bağı” from “Sultani” collection.

ST PHASE

Raw silk unwound from its cocoon is first washed in hot water of 70º-80ºC with soap. The soap is melted inside hot water in boilers, then raw silk is added inside. This process is called “cooking”. After the cooking process the silk is rinsed. Then they are left inside the boiler for dyeing process and the dye is added into the boiler. The dyeing process starts at eight o’clock in the morning by running the boiler. Around 100 kg of silk can be dyed till the evening.

ND PHASE

Following the preparation processes in the factory, dried silk are placed on looms. This process is called loom warp. The silk is warped on the looms in accordance with the desired dimensions of the carpet. The chemist performs dye study. The set of filaments necessary for the model of the carpet to be woven are prepared once loom is ready and dye process is completed. The loom and the sets are transported to the workshops for weaving.

1ST PHASE

Raw silk unwound from its cocoon is first washed in hot water of 70º-80ºC with soap. The soap is melted inside hot water in boilers, then raw silk is added inside. This process is called “cooking”. After the cooking process the silk is rinsed. Then they are left inside the boiler for dyeing process and the dye is added into the boiler. The dyeing process starts at eight o’clock in the morning by running the boiler. Around 100 kg of silk can be dyed till the evening.

2ND PHASE

Following the preparation processes in the factory, dried silk are placed on looms. This process is called loom warp. The silk is warped on the looms in accordance with the desired dimensions of the carpet. The chemist performs dye study. The set of filaments necessary for the model of the carpet to be woven are prepared once loom is ready and dye process is completed. The loom and the sets are transported to the workshops for weaving.

RD PHASE

Carpets sent for weaving are transported back to the factory. The weaving period varies, depending on the carpet dimension, from two months to one year and half. Barcodes are tagged on the carpets in the factory. After the barcode tagging is completed, quality control process starts. After the completion of these two processes the carpets are trimmed to shave off extra particles. After trimming, the carpets are transported to washing area and they are washed with chemicals and soap. Once the washing is completed, they are wringed in 2 phases. The water of small sized carpets is filtered away by spatulas. For big sized carpets water is filtered away in drum presses so that they are not bending.

TH PHASE

As the carpets submerged into water are bending, the dimensions in length and width are to be leveled. The top and the bottom of the carpets are tried to be even by the help of a punch. After this process, the dimensions of the carpets are kept intact by using wood glue. Following the process of wood glue, another steam process is applied. At last the carpets are subject to a final drying process of eight hours. Dried carpets are sent to maintenance area. The traces of punches used during the leveling of dimensions are fixed by ironing, they are controlled to see whether there is a default or not. Once final controls are performed, the carpets are ready to meet their new owners.

3RD PHASE

Carpets sent for weaving are transported back to the factory. The weaving period varies, depending on the carpet dimension, from two months to one year and half. Barcodes are tagged on the carpets in the factory. After the barcode tagging is completed, quality control process starts. After the completion of these two processes the carpets are trimmed to shave off extra particles. After trimming, the carpets are transported to washing area and they are washed with chemicals and soap. Once the washing is completed, they are wringed in 2 phases. The water of small sized carpets is filtered away by spatulas. For big sized carpets water is filtered away in drum presses so that they are not bending.

4TH PHASE

As the carpets submerged into water are bending, the dimensions in length and width are to be leveled. The top and the bottom of the carpets are tried to be even by the help of a punch. After this process, the dimensions of the carpets are kept intact by using wood glue. Following the process of wood glue, another steam process is applied. At last the carpets are subject to a final drying process of eight hours. Dried carpets are sent to maintenance area. The traces of punches used during the leveling of dimensions are fixed by ironing, they are controlled to see whether there is a default or not. Once final controls are performed, the carpets are ready to meet their new owners.

Çınar, being mentioned most often by its continuously increasing quality perception and investments made on Turkish labor and workforce, won in 2009 for the third time, the award of “American Magnificent Carpet Award” which it had already won two consecutive years previously.

Use, storage and care of handmade wool – silk carpet

· Vacuum clean the carpet smoothly once a week.

· Keep the carpet free of humidity and moisture.

· In order to prevent the dye of the carpet to fade, do not allow continuous and direct exposure to sunlight for long time.

· The carpet can have fluffs for a while depending on the used material.

· The fringes of the carpet can be deformed quicker. Please avoid vacuuming fringes.

· If there are tie knots on the surface of your carpet, cut them, do not pull them.

· Change the location of heavy objects placed on the carpet from time to time. Brush the trace of the objects with a smooth brush.

· If you face an inundation in your house and your carpets remain immerged in water, ask for professional help immediately. If you can’t have help, try only to dry the carpets by your own means.

· The washing, cleaning and care of the carpet have to be performed by qualified staff. Do not allow not qualified persons to wash, clean and care for your carpet.

Care

· Immediate intervention to the stains on your carpet, shall ease the cleaning. Therefore, liquids dropped or poured on your carpet have to be absorbed with paper towels or baby powder. Remove solid particles by a spoon.

· Do not rub on the stains. This will cause the stain get deeper in the carpet.

· While cleaning a stain, remove it from the periphery to the center. It is important for the stain to be removed successfully, to be cleaned before it spreads.

· In case the stain is not removed, ask for professional help before insisting on rubbing. Wine, tea, chemical substances and seminal stains are to be removed by professionals. If you can’t have help, wipe it out with a paper towel, letting air in from below.

The secret of Çınar, bearing this mission by constant determination is; its self-confidence on believing that it can realize more each day and the trust in that this handcraft tradition shall rise higher.

| Metric | 80 x 120 cm | 90 x 130 cm | 90 x 150 cm | 120 x 180 cm |

| US | 3′ x 5′ | 4′ x 6′ | 5′ x 7′ | |

| Metric | 150 x 230 cm | 170 x 240 cm | 200 x 280 cm | 200 x 300 cm |

| US | 6′ x 9′ | 8′ x 10′ | 9′ x 12′ | |

| Metric | 250 x 350 cm | 300 x 400 cm | 350 x 400 cm | 400 x 600 cm | 450 x 550 cm |

| US | 10′ x 14′ | 12′ x 16′ |

- Nuruosmaniye Caddesi No:4 Cağaloğlu / İstanbul TURKEY

- +90 212 513 83 17

- +90 212 513 83 10

- info@cinarhali.com.tr

- Topçular Mah. Aspendos Bulvarı No: 159 Antalya / TURKEY

- +90 242 321 83 49

- +90 242 321 83 80

- info@cinarhali.com.tr

- Organize Sanayi Bölgesi 17.Cadde No:1 Kayseri TURKEY

- +90 352 321 19 59

- info@cinarhali.com.tr

- Cumhuriyet Mah. 521 Sk. No:2 Avanos Nevşehir TURKEY

- +90 384 511 55 57

- info@cinarhali.com.tr

-

WH9 Al Khayat Avenue, Al Qouz, Dubai

United Arab Emirates - +971 56 893 1321

- info@cinarhali.com.tr